Portable Conveyor: The Ideal Solution for Efficient Material Handling

In today’s fast-paced industrial environment, the need for efficient material handling solutions is more critical than ever. Portable conveyors are designed to meet this demand, providing flexibility and convenience in various applications. Whether you’re in a warehouse, construction site, or manufacturing facility, portable conveyors can streamline your operations and enhance productivity.

Applications of Portable Conveyors

- Construction Sites: Portable conveyors can move heavy materials like sand, gravel, and concrete, making them invaluable for construction projects.

- Warehousing: In warehouses, these conveyors facilitate the movement of goods from one location to another, improving order fulfillment and inventory management.

- Agriculture: Farmers can use portable conveyors to transport grain, feed, and other materials efficiently.

- Manufacturing: In manufacturing plants, portable conveyors can streamline assembly lines and improve overall workflow.

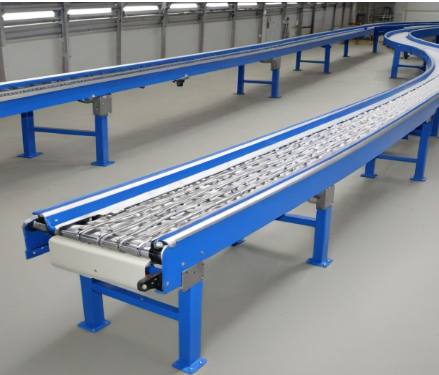

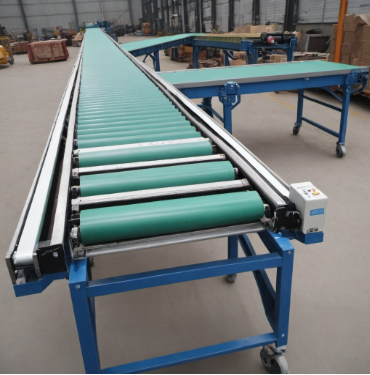

Roller Conveyor:

Roller conveyors are a popular choice for material handling in various industries due to their simplicity, versatility, and cost-effectiveness. These conveyors use a series of rollers to transport items from one location to another, making them ideal for applications such as warehousing, manufacturing, and logistics.

Types of Roller Conveyors

There are several types of roller conveyors available, each designed to meet specific needs:

- Gravity Roller Conveyors: These conveyors rely on gravity to move items along the rollers, making them suitable for short distances and light loads.

- Powered Roller Conveyors: Powered by motors, these conveyors can handle heavier loads and longer distances, offering greater control over the speed and direction of the items being transported.

- Accumulation Roller Conveyors: These conveyors are designed to hold items in a specific location until they are needed, preventing jams and ensuring smooth material flow.

- Incline/Decline Roller Conveyors: These conveyors are used to move items up or down inclines, allowing for more efficient use of space in warehouses and factories.

Horizontal Conveyors: Efficient Solutions for Material Handling

Horizontal conveyors are essential equipment in various industries, providing an effective way to transport materials across flat surfaces. These conveyors are designed to move items smoothly and efficiently, making them ideal for applications in warehouses, manufacturing plants, and distribution centers.

Benefits of Horizontal Conveyors

- Space Efficiency: Horizontal conveyors can be designed to fit into tight spaces, maximizing the use of available floor area.

- Reduced Labor Costs: By automating the movement of materials, horizontal conveyors decrease the need for manual handling, leading to significant labor cost savings.

- Increased Productivity: These conveyors streamline the material handling process, allowing for faster movement of goods and improved workflow.

- Customizable: Horizontal conveyors can be tailored to meet specific operational needs, including length, width, and load capacity.

Carton Box Conveyors: Streamlining Material Handling

Carton box conveyors are essential in modern logistics and manufacturing, designed specifically to transport cardboard boxes efficiently through various processes. These conveyors enhance productivity by automating the movement of goods, reducing manual labor, and minimizing the risk of damage during handling.

Benefits of Carton Box Conveyors

- Increased Efficiency: By automating the transportation of carton boxes, businesses can significantly speed up their operations, allowing for faster order fulfillment and improved workflow.

- Versatility: Carton box conveyors can be used in various industries, including packaging, warehousing, and distribution, making them a versatile solution for material handling.

- Reduced Labor Costs: With carton box conveyors, the need for manual handling is minimized, leading to lower labor costs and reduced risk of workplace injuries.

- Customizable Solutions: Many manufacturers offer customizable conveyor systems tailored to specific operational needs, ensuring that businesses can find the perfect fit for their requirements.

Carton Box Conveyor Manufacturers in Kanpur

For businesses in Kanpur looking for reliable carton box conveyors, several local manufacturers specialize in producing high-quality systems. These manufacturers provide a range of options, including:

- Heavy-Duty Carton Box Conveyors: Designed to handle larger loads and more demanding environments, these conveyors are perfect for industrial applications.

- Modular Carton Box Conveyors: These systems can be easily adjusted and expanded to accommodate changing operational needs.

Loading Conveyor System: Streamlining Material Handling

A loading conveyor system is an essential tool in logistics and manufacturing, designed to efficiently transport goods during the loading and unloading process. These systems enhance productivity by automating the movement of items, reducing manual labor, and minimizing the risk of injury.

Applications of Loading Conveyor Systems

Loading conveyor systems are widely used in various sectors, including:

- Warehousing: For efficient loading and unloading of goods.

- Manufacturing: To streamline production lines and facilitate the movement of materials.

- Distribution Centers: For quick and effective handling of shipments.

Loading Unloading Conveyor: Enhancing Efficiency in Material Handling

A loading unloading conveyor is a crucial piece of equipment in warehouses and distribution centers, designed to streamline the process of loading and unloading goods from trucks and containers. These conveyors facilitate the quick and efficient movement of items, significantly reducing manual labor and improving overall productivity.

Flour Bag Conveyor System: Efficient Handling for Flour Production

A flour bag conveyor system is essential for the efficient movement and handling of flour bags in milling and packaging operations. Designed to streamline the process of transporting flour from production areas to storage or shipping locations, these systems enhance productivity and minimize manual labor.

Benefits of Using a Flour Bag Conveyor System

- Increased Efficiency: By automating the transport of flour bags, businesses can significantly speed up their operations, leading to faster processing times.

- Reduced Labor Costs: With less manual handling required, companies can save on labor costs while minimizing the risk of workplace injuries.

- Improved Safety: Flour bag conveyors help reduce the risk of accidents associated with lifting and moving heavy bags manually.

Loading Unloading Conveyor Systems: Streamlining Material Handling

Loading unloading conveyor systems are essential in modern logistics and warehousing, designed to efficiently transport goods during the loading and unloading process. These systems automate the movement of materials, reducing manual labor and improving overall productivity.

Hydraulic Conveyor System: Efficient Material Handling Solution

A hydraulic conveyor system is a powerful and versatile solution designed to transport materials efficiently in various industrial applications. Utilizing hydraulic power, these systems provide smooth and controlled movement of heavy loads, making them ideal for environments where traditional conveyors may struggle.

Benefits of Using Hydraulic Conveyor Systems

- Increased Efficiency: By automating the material handling process, hydraulic conveyors significantly reduce the time and labor required for loading and unloading tasks.

- Enhanced Safety: With less manual lifting and handling, the risk of workplace injuries is minimized, creating a safer environment for employees.

- Durability: Hydraulic systems are built to withstand heavy use, providing long-lasting performance in demanding industrial settings.

Feeding Belt Conveyor System: Efficient Material Handling

A feeding belt conveyor system is an essential solution for automating the transportation of materials in various industries, particularly in agriculture, food processing, and manufacturing. Designed to efficiently move bulk materials, these systems enhance productivity by streamlining the feeding process.

Benefits of Using Feeding Belt Conveyor Systems

- Increased Efficiency: Automating the feeding process reduces manual labor and speeds up production, allowing for higher throughput.

- Reduced Labor Costs: By minimizing the need for manual handling, businesses can lower labor costs while improving safety.

- Improved Workflow: Feeding belt conveyors ensure a consistent and reliable flow of materials, enhancing overall operational efficiency.

Floor Conveyor System: Efficient Material Handling Solution

A floor conveyor system is a vital component in modern manufacturing and logistics, designed to transport materials smoothly across flat surfaces. These systems enhance operational efficiency by automating the movement of goods, making them ideal for assembly lines, warehouses, and distribution centers.

Benefits of Using Floor Conveyor Systems

- Increased Efficiency: Automating material handling processes reduces manual labor and speeds up production times.

- Cost Savings: By minimizing the need for manual handling, businesses can lower labor costs and reduce the risk of workplace injuries.

- Improved Workflow: Floor conveyor systems ensure a consistent flow of materials, enhancing overall productivity and operational efficiency.

PVC Conveyor Belts: Versatile and Durable Material Handling Solutions

PVC conveyor belts are a popular choice for a wide range of applications due to their versatility, durability, and cost-effectiveness. Made from polyvinyl chloride (PVC), these belts offer excellent resistance to wear, scratches, and chemicals, making them ideal for use in various industries such as food processing, packaging, and manufacturing.

Applications of PVC Conveyor Belts

PVC conveyor belts are widely used in various industries, including:

- Food Processing: For transporting and processing food items such as fruits, vegetables, and baked goods.

- Packaging: For moving and packaging products in manufacturing and distribution centers.

- Warehousing: For efficient material handling in warehouses and storage facilities.

- Logistics: For loading and unloading trucks and containers in transportation and logistics operations.

Screw Conveyors: Versatile Material Handling Solutions

Screw conveyors, also known as auger conveyors, are a widely used type of industrial equipment designed to transport bulk materials from one point to another. These conveyors employ a rotating helical screw blade, called a “flighting”, typically within a tube or trough, to move granular solids, semi-solids, and even liquids

Application

Used in bulk handling industries to move materials like food waste, wood chips, animal feed, and municipal solid waste

History

First type of screw conveyor was the Archimedes’ screw, used since ancient times for pumping irrigation water

Design

Consists of a trough or tube containing a spiral blade coiled around a shaft or a shaftless spiral